EASY-ROB™ steht für 20 Jahre Erfahrung in der Robotersimulation.

Mit unseren smarten Modulen steigern Sie die Wettbewerbsfähigkeit Ihrer Software erheblich. Mit unserem langjährigen Wissen über die Integration in technologiebasierte Offline-Programmiersysteme verkürzen Sie die Zeit bis zum Markteintritt entscheidend für sich.

Lassen auch Sie Ihre Applikation von EASY-ROB™ profitieren.

EASY-ROB™ – smarte Software für smarte Robotik

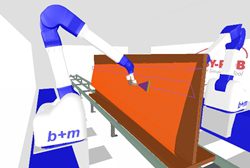

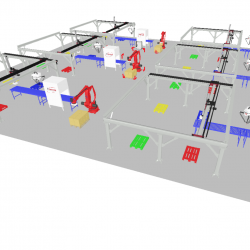

EASY-ROB™ ist eine harmonisierte Familie von Softwareprodukten für die Planung, Programmierung und Simulation verschiedenster Industrie-Roboter und Kinematiken. Ob Handling, Montage oder Beschichtung mit nur einem Roboter oder mit mehreren Robotern (Single-/Multi-Robot Version) – sämtliche Prozess- und Bewegungsabläufe können programmiert und sofort in 3D-Szenarien visualisiert werden. 100% Kompatibilität innerhalb der EASY-ROB™ Product Suite bieten Ihnen 100% Flexibilität für Ihre Simulationsanwendung und Gestaltung Ihres Softwareproduktes.

EASY-ROB™ gibt es in verschiedenen Versionen:

EASY-ROB™

Kernel

Für Softwareentwicklung ohne Visualisierung

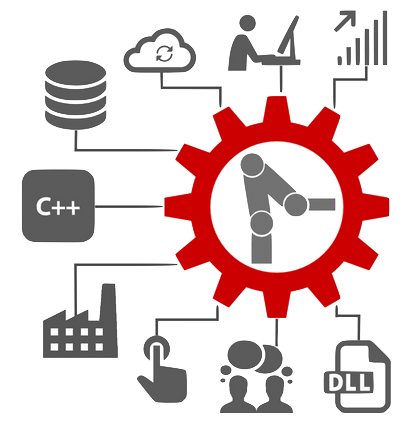

Der EASY-ROB™ Kernel (ERK) dient der Integration in technologie-basierte Software-Applikationen von OEM Partnern. Es werden ausschließlich API-Funktionen zur Verfügung gestellt. Mit dem Kernel stehen Ihnen sofort mehr als 1000 Roboter zur Verfügung.

EASY-ROB™

Framework

Für Softwareentwicklung mit Visualisierung

Das EASY-ROB™ Framework (ERF) ist ein SDK und dient zur Entwicklung von technologiebasierten Software-Applikationen für OEM Partnern. Durch die Verwendung von API-Funktionen kann das Framework vollständig angesteuert werden.

EASY-ROB™

App

Für Endanwender mit Visualisierung

Die EASY-ROB™ App (ERA) bedient alle Ihre virtuellen Prozessschritte und ist für Endanwender gedacht mit einer durchgehenden Unterstützung bei der Simulationserstellung: von der Planung der Roboterarbeitszelle, über das Prüfen von Verfahrbereichen, bis zur Präsentation.

Module

Unsere Module sind Bestandteil der verschiedenen Produkte, können aber auch einzeln erworben und in ihr System integriert werden.

- VISU

- AutoPath™

- 3D-PDF

- Collision

- APIs

- weitere Optionen